- 1 -

Desktop Hookup - Digital Submeter

The computer must have a standard, working com port (1-4) to use the software.

If there is any doubt, please verify Identifying COM Ports on your PC.

Newer PC's with USB but no com port can use adapters.USB Connections

The software installation (below pp 2-2.2) must be complete.

Software Installation - old PC with W98 or older

Software Installation - new PC with W98 or newer Shipments to first-time users are pre-configured with as much SETUP

information that was available when the order was made. The microMETER

arrives in the box with a temporary hookup so you can simply plug it in

and attempt a reading on your desktop. This should resolve most

common problems right away.

Step 1 - Connect the DB9 connector to a known, working PC comm port.

If this is not the case, determine what is available.

See Identifying COM Ports on your PC.

Step 2 - Connect power. The LED (under the terminal board) should flicker

in about 10 seconds and ever 10 seconds thereafter.

Another LED tester is included (with units shipped since 12/2/04).

See explanation in Troubleshooting - No Data.

Step 3 - Run the capture. You can do this different ways, depending on

your installation. It takes about 3 minutes to complete and it will

beep when done. If the wrong COM port is accessed, nothing will

happen and you may need to reboot the PC. If everything is OK, the

"Please wait" message should disappear after about 20 seconds. About

three minutes later it will say "Done" and beep at you. During the

capture, numbers will be "flash" behind the main panel.

with Cap2002.EXE: <-- Use this if you have W98 or better. Must use with XP,2000.

Choose the subdirectory

Choose the COM port

(This must be done twice the 1st time for Dis2002 to have before-and-after

readings to work with.) tutorial

With MICROM.EXE: <-- Use only if you have W95 or W3.x. Will work on W98.

File / Unit and Directory (default is C:\MICROMTR\MM01)

File / Capture tutorial

with MCAP.EXE or M2CAP.EXE (DOS):Downloads

Open DOS window and go to C:\MICROMTR\MM01

Type in MCAP 1 16 (enter, assuming COM 1 and the normal 16 readings) screen shot

Shipments to first-time users are pre-configured with as much SETUP

information that was available when the order was made. The microMETER

arrives in the box with a temporary hookup so you can simply plug it in

and attempt a reading on your desktop. This should resolve most

common problems right away.

Step 1 - Connect the DB9 connector to a known, working PC comm port.

If this is not the case, determine what is available.

See Identifying COM Ports on your PC.

Step 2 - Connect power. The LED (under the terminal board) should flicker

in about 10 seconds and ever 10 seconds thereafter.

Another LED tester is included (with units shipped since 12/2/04).

See explanation in Troubleshooting - No Data.

Step 3 - Run the capture. You can do this different ways, depending on

your installation. It takes about 3 minutes to complete and it will

beep when done. If the wrong COM port is accessed, nothing will

happen and you may need to reboot the PC. If everything is OK, the

"Please wait" message should disappear after about 20 seconds. About

three minutes later it will say "Done" and beep at you. During the

capture, numbers will be "flash" behind the main panel.

with Cap2002.EXE: <-- Use this if you have W98 or better. Must use with XP,2000.

Choose the subdirectory

Choose the COM port

(This must be done twice the 1st time for Dis2002 to have before-and-after

readings to work with.) tutorial

With MICROM.EXE: <-- Use only if you have W95 or W3.x. Will work on W98.

File / Unit and Directory (default is C:\MICROMTR\MM01)

File / Capture tutorial

with MCAP.EXE or M2CAP.EXE (DOS):Downloads

Open DOS window and go to C:\MICROMTR\MM01

Type in MCAP 1 16 (enter, assuming COM 1 and the normal 16 readings) screen shot

Step 4 - Display KWH. You can do this different ways, depending on

your installation. Program should not fail with an incomplete file.

If this happens, there was a problem in Step 3. You should see 0

amperes on channel 1 (or whatever you may have put through the

attached CT). You may see maximum amperes appear on other channels

you intend to use that do not have CT's connected yet.

with Dis2002.EXE: <-- Use this if you have W98 or better. Must use with XP,2000.

Choose the subdirectory

Choose the first and second captures (There must be at least 2.)

Click "mm.htm"

Click "ie browser" (or open a different browser and view mm.htm) tutorial

With MICROM.EXE: <-- Use only if you have W95 or W3.x. Will work on W98.

File / Unit and Directory (default is C:\MICROMTR\MM01)

Display / KWH tutorial

with DIS.EXE (DOS):Downloads

Open DOS window and go to C:\MICROMTR\MM01

Type in DIS (enter) screen shot

The first time you may see some residual values from calibration that

are not due to your usage. Click Reset/All to clear them out. Dis2002.EXE

does not use resets. Any pair of readings can be viewed.

We can also supply the software pre-installed to run from a USB memory stick.

- 2 -

See Vista for other methods for (Vista, Windows 7 - 10) pc's. The software, old and new, makes very little demand of a PC. Often a "junker"

can be dedicated to the job. For those wanting to utilize the "latest and greatest",

there are still some caveats:

1) 9/12/2007 - Be sure the pc's operating system supports serial communications. Some recent "home

versions" are omitting this support. Specify at the time of purchase that you need serial

capability and (preferably) get a built-in com port. The com port has 9 pins in 2 rows and is usually

found in the rear. See Identifying COM Ports on your PC.

2) 11/20/2007 - Avoid proprietary systems. If you are using a Compaq or HP box,

do not put anything in the root directory. Copy the cd folder "micromtr" to the desktop.

3) Avoid overloaded systems (10 lbs. in a 5 lb. bag). A corporate PC with

a time clock connection, security monitors, etc. had no usable com port

in spite of assurances that it did from the local support technician.

4) Avoid crippled systems. A corporate PC with standard o/s components

disabled or removed can be difficult to work with if direct access to files

and utilities is thwarted.

5) 02/25/2011 - from http://en.wikipedia.org/wiki/Serial_port#Settings

Many personal computer motherboards still have at least one serial port, even if accessible only through a pin

header. Small-form-factor systems and laptops may omit RS-232 connector ports to conserve space, but the

electronics are still there. RS-232 has been standard for so long that the circuits needed to control a serial

port became very cheap and often exist on a single chip, sometimes also with circuitry for a parallel port.

Any form of remote desktop access will, of course, make reports available from anywhere.

New browser-based software development is also reducing platform dependencies.

Reports and files are html/text-based to maximize compatibility.

Using the configuration CD:

Step 1 - Drag the CDROM folder micromtr to your pc desktop. Ignore anything else on the CD.

This should create a main folder called micromtr with subfolders mm01, etc.

This will contain your customized files per correspondence.

The "recovery" folder contains extra files only if they are needed.

Proceed to Step 3.

04/22/2008 - Using the email-attached, configuration zip file microzip:

Step 1 - Save the self-extracting file microzip.zip to your desktop.

Step 2 - Doubleclick into it and extract all files.

Note: This will put the folder "micromtr" inside a desktop folder called "microzip".

Finish the installation:

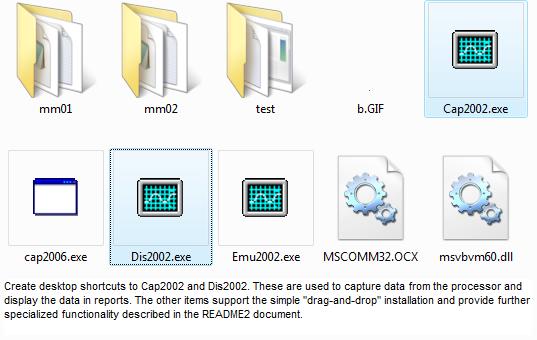

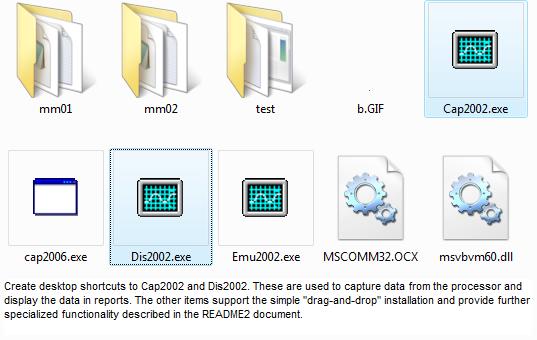

Step 3 - If desired, create desktop shortcuts to run micromtr\Cap2002.EXE and

micromtr\Dis2002.EXE.

Step 4 - Verify the following micromtr directory structures before proceeding.

micromtr

Cap2002 EXE - The capture program that reads the com port and builds the database.

Dis2002 EXE - The display program that reads the database and creates the reports.

b gif - a graphic pixel used by Dis2002.EXE

mscomm32.ocx - MS runtime file - If placed here, there is no need to disturb anything else on your pc.

msvbvm60.dll - MS runtime file - If placed here, there is no need to disturb anything else on your pc.

mm01 (directory) - You may have as many more as needed, mm02, etc. Customized

folders may have different names, usually 4 characters long based on your request. May appear as mm01, etc.

TEST (directory) - simply to run captures or test other items without affecting anything else.

micromtr\mm01

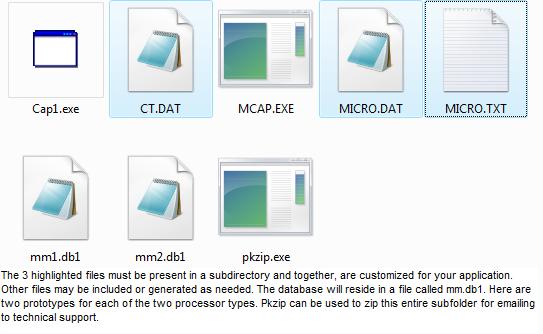

CT DAT 1,168 05-28-96 12:46p CT.DAT

MICRO TXT 438 01-15-96 5:46p MICRO.TXT

MICRO DAT 175 02-01-96 9:34p MICRO.DAT

Several data files for one mM can be on \micromtr\mm01 but only these three are needed

to start the new software. There should be no subdirectories under this one.

Any additional subdirectories (folders) nested under \micromtr\mm01 will cause

Dis2002.EXE to fail with a "problem with MM.DB1 file" message.

A few new filenames will be created later when programs are used. MM.DB1 is the main database.

The software, old and new, makes very little demand of a PC. Often a "junker"

can be dedicated to the job. For those wanting to utilize the "latest and greatest",

there are still some caveats:

1) 9/12/2007 - Be sure the pc's operating system supports serial communications. Some recent "home

versions" are omitting this support. Specify at the time of purchase that you need serial

capability and (preferably) get a built-in com port. The com port has 9 pins in 2 rows and is usually

found in the rear. See Identifying COM Ports on your PC.

2) 11/20/2007 - Avoid proprietary systems. If you are using a Compaq or HP box,

do not put anything in the root directory. Copy the cd folder "micromtr" to the desktop.

3) Avoid overloaded systems (10 lbs. in a 5 lb. bag). A corporate PC with

a time clock connection, security monitors, etc. had no usable com port

in spite of assurances that it did from the local support technician.

4) Avoid crippled systems. A corporate PC with standard o/s components

disabled or removed can be difficult to work with if direct access to files

and utilities is thwarted.

5) 02/25/2011 - from http://en.wikipedia.org/wiki/Serial_port#Settings

Many personal computer motherboards still have at least one serial port, even if accessible only through a pin

header. Small-form-factor systems and laptops may omit RS-232 connector ports to conserve space, but the

electronics are still there. RS-232 has been standard for so long that the circuits needed to control a serial

port became very cheap and often exist on a single chip, sometimes also with circuitry for a parallel port.

Any form of remote desktop access will, of course, make reports available from anywhere.

New browser-based software development is also reducing platform dependencies.

Reports and files are html/text-based to maximize compatibility.

Using the configuration CD:

Step 1 - Drag the CDROM folder micromtr to your pc desktop. Ignore anything else on the CD.

This should create a main folder called micromtr with subfolders mm01, etc.

This will contain your customized files per correspondence.

The "recovery" folder contains extra files only if they are needed.

Proceed to Step 3.

04/22/2008 - Using the email-attached, configuration zip file microzip:

Step 1 - Save the self-extracting file microzip.zip to your desktop.

Step 2 - Doubleclick into it and extract all files.

Note: This will put the folder "micromtr" inside a desktop folder called "microzip".

Finish the installation:

Step 3 - If desired, create desktop shortcuts to run micromtr\Cap2002.EXE and

micromtr\Dis2002.EXE.

Step 4 - Verify the following micromtr directory structures before proceeding.

micromtr

Cap2002 EXE - The capture program that reads the com port and builds the database.

Dis2002 EXE - The display program that reads the database and creates the reports.

b gif - a graphic pixel used by Dis2002.EXE

mscomm32.ocx - MS runtime file - If placed here, there is no need to disturb anything else on your pc.

msvbvm60.dll - MS runtime file - If placed here, there is no need to disturb anything else on your pc.

mm01 (directory) - You may have as many more as needed, mm02, etc. Customized

folders may have different names, usually 4 characters long based on your request. May appear as mm01, etc.

TEST (directory) - simply to run captures or test other items without affecting anything else.

micromtr\mm01

CT DAT 1,168 05-28-96 12:46p CT.DAT

MICRO TXT 438 01-15-96 5:46p MICRO.TXT

MICRO DAT 175 02-01-96 9:34p MICRO.DAT

Several data files for one mM can be on \micromtr\mm01 but only these three are needed

to start the new software. There should be no subdirectories under this one.

Any additional subdirectories (folders) nested under \micromtr\mm01 will cause

Dis2002.EXE to fail with a "problem with MM.DB1 file" message.

A few new filenames will be created later when programs are used. MM.DB1 is the main database.

Check Type 1 (discontinued) or Type 2 at the bottom of the form (v1.18).

Software Installation - older PC with W98 and older

Check Type 1 (discontinued) or Type 2 at the bottom of the form (v1.18).

Software Installation - older PC with W98 and older tutorial

The Windows program MICROM.EXE can utilize COM 1,2,3 or 4 using Win 98 or older.

Please see the DOS Archive for earlier program notes.

Note 11/13/04 - The floppy is no longer supplied. Instead, a folder on the CD

called "floppy" will contain the customized files and the INSTALL.BAT file.

Transfer this to a floppy disk.

1/5/06 - Windows does not recognize my file suffixes .dat and .db1 as text files.

Right-click open and "choose program from a list" (notepad)

Check the box below to always open with notepad.

It is assumed that the PC has a hard drive called C: with no directory

called MICROMTR and a floppy drive called A:

Step 1 - Place the diskette in A: and execute INSTALL.BAT from A:

Step 2 - Verify the following result before proceeding.

If the files wound up elsewhere,

manually copy them to these directories:

About 5 files should be on C:\MICROMTR. They are:

MICROM EXE 62,489 03-31-98 12:29a MICROM.EXE

VBRUN300 DLL 398,416 09-14-96 3:09p VBRUN300.DLL

VBCOMM VBX 9,296 08-22-92 10:00p VBCOMM.VBX

README2 TXT 05-08-01 6:23p readme2.txt (redirected to website)

README TXT 05-08-01 6:23p readme.txt (redirected to website)

MM01 (directory) You may create as many more as needed, MM02, etc.

About 11-12 files should be on C:\MICROMTR\MM01 (data files for one mM).

There should be no subdirectories under this one.

CT DAT 1,168 05-28-96 12:46p CT.DAT

MICRO TXT 438 01-15-96 5:46p MICRO.TXT

MCAP EXE 45,734 07-22-96 11:28a MCAP.EXE

MICRO DAT 175 02-01-96 9:34p MICRO.DAT

XX CAP 292 12-19-96 10:15a XX.CAP

CT DTE 336 05-04-95 6:57p CT.DTE

MICRO2 CAP 336 12-19-96 10:16a MICRO2.CAP

MM BAT 320 03-08-99 12:59p MM.BAT

CT RES 279 05-04-95 6:57p CT.RES

MICRO PRT 1,632 12-31-99 6:41p MICRO.PRT

CT CAP 279 01-10-99 12:36p ct.cap

DIS EXE <-- add this file from download if needed for DOS display

Step 3 - Create a desktop shortcut to run C:\MICROMTR\MICROM.EXE.

tutorial

The Windows program MICROM.EXE can utilize COM 1,2,3 or 4 using Win 98 or older.

Please see the DOS Archive for earlier program notes.

Note 11/13/04 - The floppy is no longer supplied. Instead, a folder on the CD

called "floppy" will contain the customized files and the INSTALL.BAT file.

Transfer this to a floppy disk.

1/5/06 - Windows does not recognize my file suffixes .dat and .db1 as text files.

Right-click open and "choose program from a list" (notepad)

Check the box below to always open with notepad.

It is assumed that the PC has a hard drive called C: with no directory

called MICROMTR and a floppy drive called A:

Step 1 - Place the diskette in A: and execute INSTALL.BAT from A:

Step 2 - Verify the following result before proceeding.

If the files wound up elsewhere,

manually copy them to these directories:

About 5 files should be on C:\MICROMTR. They are:

MICROM EXE 62,489 03-31-98 12:29a MICROM.EXE

VBRUN300 DLL 398,416 09-14-96 3:09p VBRUN300.DLL

VBCOMM VBX 9,296 08-22-92 10:00p VBCOMM.VBX

README2 TXT 05-08-01 6:23p readme2.txt (redirected to website)

README TXT 05-08-01 6:23p readme.txt (redirected to website)

MM01 (directory) You may create as many more as needed, MM02, etc.

About 11-12 files should be on C:\MICROMTR\MM01 (data files for one mM).

There should be no subdirectories under this one.

CT DAT 1,168 05-28-96 12:46p CT.DAT

MICRO TXT 438 01-15-96 5:46p MICRO.TXT

MCAP EXE 45,734 07-22-96 11:28a MCAP.EXE

MICRO DAT 175 02-01-96 9:34p MICRO.DAT

XX CAP 292 12-19-96 10:15a XX.CAP

CT DTE 336 05-04-95 6:57p CT.DTE

MICRO2 CAP 336 12-19-96 10:16a MICRO2.CAP

MM BAT 320 03-08-99 12:59p MM.BAT

CT RES 279 05-04-95 6:57p CT.RES

MICRO PRT 1,632 12-31-99 6:41p MICRO.PRT

CT CAP 279 01-10-99 12:36p ct.cap

DIS EXE <-- add this file from download if needed for DOS display

Step 3 - Create a desktop shortcut to run C:\MICROMTR\MICROM.EXE.

- 3 -

DOS Program Summary

Billing Suite:

Input files Executable program Output files

COM port CAP.EXE (obsolete) CT.CAP, MICRO2.CAP

MCAP.EXE (modem supt)

3CAP.EXE (3-phase)

MONITOR.EXE (alarm)

MMICAPPG.EXE (COM 3,4)

TCAP.EXE

CT.DAT, MICRO.DAT SETUP.EXE CT.DAT, MICRO.DAT

CT.CAP, MICRO2.CAP DIS.EXE MICRO.PRT

CT.RES, CT.DTE

CT.DAT, MICRO.DAT

MICRO.TXT (1st line)

CT.CAP, MICRO2.CAP RESET.EXE CT.BIL, CT.BI2

CT.RES, CT.DTE CT.RES, CT.DTE

CT.DAT, MICRO.DAT

Advanced Billing:

Input files Executable program Output files

CT.BIL, CT.AFF MAP.EXE CUS.BIL

Produces CUS.BIL from concatenated

CT.BIL('s) to consolidate as directed

in CT.AFF. Copy back to CT.BIL

CT.BIL, MICRO.TXT PRTBILL.EXE BILLS.OUT

Produces formatted bills,

4 to a page in an ASCII file

CT.BIL SUMM.EXE CT.SUM

Adds one or multiple CT.BIL and

reconciles total to statement.

Analytical Suite:

Input files Executable program Output files

USAGE.CAP USAG4.EXE USAGE.Pxx

Produces USAGE.Pxx (17 24-hour

files from USAGE.CAP (8640 CT.CAP))

USAGE.Pxx PLOT4.EXE Screen VGA plot of amp,KW over time

USAGE.Pxx DEMAND.EXE DEMAND.OUT

Produces 15, 30 or 60 minute

interval data for all CT's

DEMAND.OUT DSPLIT.EXE DSPLIT.OUT

Produces plot data for 1 CT

or system total (CT 17).

DSPLIT.OUT PLOT4.EXE Screen VGA plot of amp,KW over time

CT.CAP, MICRO2.CAP DISPF.EXE Screen

CT.RES, CT.DTE Produces power factor display

CT.DAT, MICRO.DAT for paired channels using powerstats kit.

MICRO.TXT (1st line) Run in DOS with redirected output to create print file.

Utility Suite:

Input files Executable program Output files

SEP.INP SEP.EXE SEP.OUT

Partition larger files into smaller ones.

CT.BIL COMMA.EXE COMMA.OUT

Comma delimit CT.BIL for spreadsheet import.

CT.BIL IDEAL.EXE IDEAL.OUT

Produce IDEAL(tm) extract.

any SHOW.EXE screen

Use to examine the README files on your screen.

any PRTDOC.EXE printer

Use to print the README files by page number.

Note: These are all archived in the download page.

download

- 4 -

DOS Program Detailed Descriptions

*** USAG4.EXE

USAG4.EXE produces time-axis graphs of power usage over a 24

hour period. Run the CAPture program with 8640 readings.

This will require 24 hours to complete. At completion,

CAPture will start the DISplay program. Exit the DISplay

program and rename the CT.CAP file to USAGE.CAP. Rename

MICRO2.CAP to USAGE.DTE.

Run USAG4 (without any parameters or prompts). It will

produce 17 files of the form USAGE.Pxx where xx is 01 thru

17. Then run PLOT4. A series of 17 VGA plots will appear.

The files called USAGE.Pxx have 540 records (8640/16) for

each CT and the system total. They can be imported to a

spreadsheet. Records contain ampere data.

*** DEMAND.EXE, DSPLIT.EXE, PLOT4.EXE:

DEMAND.EXE and DSPLIT.EXE can be used to collect demand data

in 15, 30 and 60 minute intervals. DEMAND.EXE reads a copy of

CT.CAP that is renamed to USAGE.CAP and puts out a file

called DEMAND.OUT. This file has the CT# and max kw for 30

minute intervals in 816 records (which represents 17 sets of

48). CT 17 is the system total. DSPLIT.EXE filters

DEMAND.OUT into DSPLIT.OUT for a specific CT and drops the

CT# to save disk space, resulting in 48 records. Follow with

PLOT4.EXE.

*** MONITOR.EXE:

MONITOR.EXE can be run instead of CAP.EXE to capture only

those readings exceeding high or low limits entered by the

user. It runs until stopped manually and stores exception

data in CT.CAP and corresponding time and date in MICRO2.CAP.

It can give an alarm when exceptions occur. High and low

limits are in raw scale form (0-255) which must be

interpreted for the corresponding CT size.

*** MMICAPPG.EXE

Lockheed Martin substitute for CAP.EXE with COM3 and COM4

operational.

*** MCAP.EXE

Functionally equivalent to CAP.EXE but combines modem control

and multiple microMETER select (see SWITCH below). This runs

from a batch file and has no prompts. See examples in MM.BAT

*** PRTBILL.EXE (PRTBILL 22)

Produces BILLS.OUT text file from CT.BIL and MICRO.TXT

Add parameter 22 to put 22 blank lines after each set of 4

bills. Vary this to make DOS PRINT print your bills four-to-

a-page on your printer.

- 4.5 -

DOS/Windows Instructions for capture thru mouse port

This was a very common scenario. An older PC has a mouse and modem tying up

COM1 and COM2. Usually the mouse is on COM1 and attaches with a 9-pin

female D connector in the back. Install this .BAT file and use the

following instructions:

Put MM.BAT in the C:\windows directory and install DIS.EXE in the

C:|MICROMTR\MM01 directory

echo off

cd\MICROMTR\MM01

mcap 1 00016 0...............

dis rem (if desired for immediate DOS display)

cls

echo Reconnect mouse and disconnect mM at pole to protect from lightning.

echo Type exit (enter)

echo Click up mM icon to view, reset all and print bills.

pause

microMETER Instructions

1) Restart in DOS mode (not the Windows DOS prompt)

2) MM (enter)

connect MM at PC and pole (phone jack)

(Capture will take 3 minutes - press enter)

Print screen now, if desired - use print screen key at upper right)

0 to exit DOS display

3) Connect mouse, diconnect mM at pole (phone jack) - press enter

4) Type EXIT, press enter

5) Double click mM icon

6) Display, KWH

7) Reset, All

8) Reset, Print Bills (if desired)

9) Close

To further ID circuits:

Repeat 2) looking for AMPS = 0

Another, very simplified method for reading more than one processor:

simple batfiles for mm

1.bat - put this where DOS "lands"

cd\micromtr\mm01

mcap 1,16

dis enter 0 to exit

reset 17

cd\micromtr\mm02

2.bat - put this in mm02

mcap 1,16

dis enter 0 to exit

reset 17

exit

procedure:

Connect at both poles.

Attach plug 1 to pc.

click up DOS and enter the following:

1

0

change to plug 2 and enter the following:

2

0

click up reports (on desktop) and print.

Disconnect at poles.

- 10 -

DOS/Windows Data Files

All these files can be accessed with a plain text editor.

Use this Handy-Dandy Ruler for checking field lengths and starting positions:

....+....1....+....2....+....3....+....4....+....5....+....6....+....7....+....8

0 0 0 0 0 0 0 0

Files 1-3 are used universally by all s/w. They represent your configuration.

1. MICRO.DAT

12.75 (This is fixed for v1.04 microMETER hardware)

2390.625 (286875 / your avg line voltage if using RMS)

6.96 (cents / kwh)

1=color/0=mono (used for default COM Port in Windows Program)

3 rows of 4 numbers - special meanings for various programs

example:

12.75

2515.632

8.5

1

0 1 2 3

4 5 6 7

7 7 0 0

Line 5 1st number: 0=non-analytic mMI or mMII - alternating row color in Dis2002.EXE

Line 5 1st number: 2=analytic mMI - paired row color in Dis2002.EXE and special pf calc

Line 5 1st number: 3=3-phase mMII - triple row color in Dis2002.EXE

Line 5 2nd number: 0=unselect true power in Dis2002 display (v1.15)

2. MICRO.TXT

Company name (1st line) and text for DISplay and PRTBILL (7 lines total)

microMETER Corp.

Energy usage charges due and payable for the period ending.

Taxes and customer charges have been added proportionately.

Thank you for your prompt payment.

Customer Billing Period Usage Amount Due

Rate: Non-demand, Non-TOU - Customer chg incl. @ xxxx cts/kwh

3. CT.DAT

CT #1 descr, CT size, power factor, circuit voltage, low alarm limit, high alarm limit

CT #2 descr, CT size, power factor, circuit voltage, low alarm limit, high alarm limit

...

Use this Handy-Dandy Ruler for checking field lengths and starting positions:

....+....1....+....2....+....3....+....4....+....5....+....6....+....7....+....8

0 0 0 0 0 0 0 0

example: period is used to reserve space

1 - Range "0040,1.00,240,000,999 .

2 - Kitchen "0020,1.00,120,000,999 .

3 - Water Heater "0020,1.00,240,000,999 .

4 - Refrigerator "0020,1.00,120,000,999 .

5 - Pumphouse "0020,1.00,120,000,999 .

6 - Pool "0020,1.00,240,000,999 .

7 - Well Pump "0020,1.00,120,000,999 .

8 - Air Handler "0020,1.00,240,000,999 .

9 - Laundry Room "0020,1.00,120,000,999 .

10 - Living Room, Attic "0020,1.00,120,000,999 .

11 - Small Bedrooms "0020,1.00,120,000,999 .

12 - Dryer "0020,1.00,240,000,999 .

13 - A/C "0020,1.00,240,000,999 .

14 - Garage "0020,1.00,120,000,999 .

15 - "0000,1.00,120,000,999 .

16 - "0000,1.00,120,000,999 .

The low,high alarm limits ------------> 000,999 are passive until changed. Setting the

low limit above 000 or setting the high limit below 254 will trigger alarm related events

in any programs that use them. They are compared to the raw pulse count (second number from mM).

Use this Handy-Dandy Ruler for checking field lengths and starting positions:

....+....1....+....2....+....3....+....4....+....5....+....6....+....7....+....8

0 0 0 0 0 0 0 0

----------------- legacy files used by MICROM.EXE and DOS programs

All these files can be accessed with a plain text editor.

Use this Handy-Dandy Ruler for checking field lengths and starting positions:

....+....1....+....2....+....3....+....4....+....5....+....6....+....7....+....8

0 0 0 0 0 0 0 0

Files 1-3 are used universally by all s/w. They represent your configuration.

1. MICRO.DAT

12.75 (This is fixed for v1.04 microMETER hardware)

2390.625 (286875 / your avg line voltage if using RMS)

6.96 (cents / kwh)

1=color/0=mono (used for default COM Port in Windows Program)

3 rows of 4 numbers - special meanings for various programs

example:

12.75

2515.632

8.5

1

0 1 2 3

4 5 6 7

7 7 0 0

Line 5 1st number: 0=non-analytic mMI or mMII - alternating row color in Dis2002.EXE

Line 5 1st number: 2=analytic mMI - paired row color in Dis2002.EXE and special pf calc

Line 5 1st number: 3=3-phase mMII - triple row color in Dis2002.EXE

Line 5 2nd number: 0=unselect true power in Dis2002 display (v1.15)

2. MICRO.TXT

Company name (1st line) and text for DISplay and PRTBILL (7 lines total)

microMETER Corp.

Energy usage charges due and payable for the period ending.

Taxes and customer charges have been added proportionately.

Thank you for your prompt payment.

Customer Billing Period Usage Amount Due

Rate: Non-demand, Non-TOU - Customer chg incl. @ xxxx cts/kwh

3. CT.DAT

CT #1 descr, CT size, power factor, circuit voltage, low alarm limit, high alarm limit

CT #2 descr, CT size, power factor, circuit voltage, low alarm limit, high alarm limit

...

Use this Handy-Dandy Ruler for checking field lengths and starting positions:

....+....1....+....2....+....3....+....4....+....5....+....6....+....7....+....8

0 0 0 0 0 0 0 0

example: period is used to reserve space

1 - Range "0040,1.00,240,000,999 .

2 - Kitchen "0020,1.00,120,000,999 .

3 - Water Heater "0020,1.00,240,000,999 .

4 - Refrigerator "0020,1.00,120,000,999 .

5 - Pumphouse "0020,1.00,120,000,999 .

6 - Pool "0020,1.00,240,000,999 .

7 - Well Pump "0020,1.00,120,000,999 .

8 - Air Handler "0020,1.00,240,000,999 .

9 - Laundry Room "0020,1.00,120,000,999 .

10 - Living Room, Attic "0020,1.00,120,000,999 .

11 - Small Bedrooms "0020,1.00,120,000,999 .

12 - Dryer "0020,1.00,240,000,999 .

13 - A/C "0020,1.00,240,000,999 .

14 - Garage "0020,1.00,120,000,999 .

15 - "0000,1.00,120,000,999 .

16 - "0000,1.00,120,000,999 .

The low,high alarm limits ------------> 000,999 are passive until changed. Setting the

low limit above 000 or setting the high limit below 254 will trigger alarm related events

in any programs that use them. They are compared to the raw pulse count (second number from mM).

Use this Handy-Dandy Ruler for checking field lengths and starting positions:

....+....1....+....2....+....3....+....4....+....5....+....6....+....7....+....8

0 0 0 0 0 0 0 0

----------------- legacy files used by MICROM.EXE and DOS programs  ------------------------

Files 4-7 represent any given time span in the legacy s/w.

4. CT.CAP

CT#, current analog, kwh low bucket, kwh high bucket

...

example:

16,000,65391,00001 Note: It starts wherever the mM happens to be.

01,238,48529,00048

02,012,45922,00153

03,000,42821,00236

04,023,32445,00457

05,003,07966,00035

06,000,22206,00236

07,000,27452,00003

08,014,44283,00159

09,015,62512,00128

10,000,62684,00052

11,016,39015,00096

12,000,43977,00067

13,166,63162,00594

14,003,10802,00127

15,000,65385,00009

5. CT.RES

copy of CT.CAP data at last reset (to be subtracted from next CT.CAP)

6. MICRO2.CAP

time, date corresponding to CT.CAP

example:

19:43:48 07-17-2003

19:43:57 07-17-2003

19:44:07 07-17-2003

19:44:17 07-17-2003

19:44:27 07-17-2003

19:44:37 07-17-2003

19:44:47 07-17-2003

19:44:57 07-17-2003

19:45:07 07-17-2003

19:45:17 07-17-2003

19:45:27 07-17-2003

19:45:37 07-17-2003

19:45:47 07-17-2003

19:45:57 07-17-2003

19:46:07 07-17-2003

19:46:17 07-17-2003

7. CT.DTE

copy of MICRO2.CAP data at last reset

8. CT.BIL (CT.BI2 has same data appended to old and never cleared)

CT descr, kwh, $, from reset date, to date of billing

4 - Refrigerator 10-16-1995 to 01-08-1996 252 kwh $ 21.41

....+....1....+....2....+....3....+....4....+....5....+....6....+....7....+....8

0 0 0 0 0 0 0 0

9. MICRO.PRT

screen displays from DIS.EXE for emailing, remote printing, etc.

------------------------

Files 4-7 represent any given time span in the legacy s/w.

4. CT.CAP

CT#, current analog, kwh low bucket, kwh high bucket

...

example:

16,000,65391,00001 Note: It starts wherever the mM happens to be.

01,238,48529,00048

02,012,45922,00153

03,000,42821,00236

04,023,32445,00457

05,003,07966,00035

06,000,22206,00236

07,000,27452,00003

08,014,44283,00159

09,015,62512,00128

10,000,62684,00052

11,016,39015,00096

12,000,43977,00067

13,166,63162,00594

14,003,10802,00127

15,000,65385,00009

5. CT.RES

copy of CT.CAP data at last reset (to be subtracted from next CT.CAP)

6. MICRO2.CAP

time, date corresponding to CT.CAP

example:

19:43:48 07-17-2003

19:43:57 07-17-2003

19:44:07 07-17-2003

19:44:17 07-17-2003

19:44:27 07-17-2003

19:44:37 07-17-2003

19:44:47 07-17-2003

19:44:57 07-17-2003

19:45:07 07-17-2003

19:45:17 07-17-2003

19:45:27 07-17-2003

19:45:37 07-17-2003

19:45:47 07-17-2003

19:45:57 07-17-2003

19:46:07 07-17-2003

19:46:17 07-17-2003

7. CT.DTE

copy of MICRO2.CAP data at last reset

8. CT.BIL (CT.BI2 has same data appended to old and never cleared)

CT descr, kwh, $, from reset date, to date of billing

4 - Refrigerator 10-16-1995 to 01-08-1996 252 kwh $ 21.41

....+....1....+....2....+....3....+....4....+....5....+....6....+....7....+....8

0 0 0 0 0 0 0 0

9. MICRO.PRT

screen displays from DIS.EXE for emailing, remote printing, etc.

- 11 -

Windows Program MICROM.EXE  MICROM.EXE screen shot

A Windows gui program is available to replace all of the DOS

programs and provide a more user friendly interface.

It is designed to operate from a directory called

C:\MICROMTR and support several mM's installed in subdirectories

called MM01, MM02, etc.

The subdirectories require the CT.xxx

and MICROx.xxx files that are specific to each unit. The

executables reside in one place under C:\MICROMTR. For DOS

compatibility, the DOS executables must be copied into each

of the subdirectories. The Windows program uses some MICRO.DAT

parameters for different purposes and may affect the color

display in DIS.EXE. The executable is MICROM.EXE and requires

VBRUN300.DLL and VBCOMM.VBX to be present.

download

Using Windows "RUN" or "FIND" features, locate the MICROM.EXE

program in C:\MICROMTR. Right click the MICROM.EXE. A shortcut

will appear. Drag the shortcut to the desktop.

The functions of the DOS programs were implemented in

dropdown menus. Some dropdowns toggle a setting that affects

another dropdown. For example, ALTERNATE will do nothing when

clicked but the next time KWH is clicked, the alternate

display will appear. Resetting certain CT's (not all)

requires a little tag (lowercase r) to be placed in the

textboxes. Clicking SELECTIVE (under RESET) will reset only

those CT's so marked. If you understand the DOS functions,

the Windows version will be easy to adapt to. If you are new

to the microMETER software, the Windows version should be

easier to learn. We welcome suggestions and make changes to

improve our system for our clients.

download

MICROM.EXE Dropdown menus:

FILE ********

Unit and Directory - Use to set the correct data directory for a

particular mM. Also use to select the desired mM unit via an

optional switch. The hex codes 0-F correspond to MM01-mm16. A

COM port override selects COM1-4. A modem can be dialed with a

number entered on this panel.

Dial - Establishes remote connection by dialing the number entered

above. Watch external modem to see carrier detect before

proceeding with CAPTURE

Capture - initiates capture of 16 readings through the selected COM

port. Watch for "done" message when complete. Follow with HANGUP if

using a modem.

24-Hour - Same as CAPTURE but 8640 readings are captured into USAGE

files. THIS WILL NOT UPDATE THE DISPLAY. This process completes

in 24 hours and may be minimized to allow other PC activity.

Hangup - Hang up modem following a remote capture (or 24 hour).

Exit - Return to Windows.

DISPLAY ********

KWH - Click to display captured data (following CAPTURE)

Alternate - Click to toggle display mode to KW, then click KWH

Reconcile to - After placing the kwh from your utility bill in

the bottom kwh box, click to force data to add up to this

new value. Click DISPLAY again to see the result.

Temperatures - If thermistors are used to collect temperature data

on unused kwh channels, the results will be displayed separately

from the kwh data. Alternate toggle selects degrees C.

SETUP ********

CT - Enter CT descriptive data on this panel.

microMETER - Use to enter global data for all the mM channels.

RESET ********

Selective - Click to reset any channel(s) with a lowercase "r" entered

at the leftmost position of the circuit name box.

All - Click to generate billing data and clear the kwh readings.

Print Bills - Click (after a RESET) to print the billing data.

Unreset - Restores ALL kwh accrued since the mM was installed.

This is NOT used in normal monthly billing procedures.

ABOUT ******** Displays "ABOUT" information

HELP ********

Readme - Displays the README.TXT file

Readme2 - Displays the README2.TXT file

24 HOUR DEMAND ********

Process New Data - After a 24 hour capture has been completed, click

this entry to process the data. It takes about 15 minutes and only

needs to be done once. Any previous demand data graphics will be

lost. If desired, save the USAGE.Pxx, DEMxx.Pxx files first.

View - Access any of the processed data. Note that interval demand

data will not be available until processed by the PROCESS DEMAND

entry at the end of this menu.

Instantaneous Select - After viewing any interval data, click to make

View show the instantaneous graphs again.

15 Minute Select - Changes View pointer to 15 minute graphs

30 Minute Select - Changes View pointer to 30 minute graphs

60 Minute Select - Changes View pointer to 60 minute graphs

Process Demand - Click to further process the 24 hour data prior

to viewing any intervals (15, 30, 60). This takes a few minutes

and is only run once for new data.

download

MICROM.EXE screen shot

A Windows gui program is available to replace all of the DOS

programs and provide a more user friendly interface.

It is designed to operate from a directory called

C:\MICROMTR and support several mM's installed in subdirectories

called MM01, MM02, etc.

The subdirectories require the CT.xxx

and MICROx.xxx files that are specific to each unit. The

executables reside in one place under C:\MICROMTR. For DOS

compatibility, the DOS executables must be copied into each

of the subdirectories. The Windows program uses some MICRO.DAT

parameters for different purposes and may affect the color

display in DIS.EXE. The executable is MICROM.EXE and requires

VBRUN300.DLL and VBCOMM.VBX to be present.

download

Using Windows "RUN" or "FIND" features, locate the MICROM.EXE

program in C:\MICROMTR. Right click the MICROM.EXE. A shortcut

will appear. Drag the shortcut to the desktop.

The functions of the DOS programs were implemented in

dropdown menus. Some dropdowns toggle a setting that affects

another dropdown. For example, ALTERNATE will do nothing when

clicked but the next time KWH is clicked, the alternate

display will appear. Resetting certain CT's (not all)

requires a little tag (lowercase r) to be placed in the

textboxes. Clicking SELECTIVE (under RESET) will reset only

those CT's so marked. If you understand the DOS functions,

the Windows version will be easy to adapt to. If you are new

to the microMETER software, the Windows version should be

easier to learn. We welcome suggestions and make changes to

improve our system for our clients.

download

MICROM.EXE Dropdown menus:

FILE ********

Unit and Directory - Use to set the correct data directory for a

particular mM. Also use to select the desired mM unit via an

optional switch. The hex codes 0-F correspond to MM01-mm16. A

COM port override selects COM1-4. A modem can be dialed with a

number entered on this panel.

Dial - Establishes remote connection by dialing the number entered

above. Watch external modem to see carrier detect before

proceeding with CAPTURE

Capture - initiates capture of 16 readings through the selected COM

port. Watch for "done" message when complete. Follow with HANGUP if

using a modem.

24-Hour - Same as CAPTURE but 8640 readings are captured into USAGE

files. THIS WILL NOT UPDATE THE DISPLAY. This process completes

in 24 hours and may be minimized to allow other PC activity.

Hangup - Hang up modem following a remote capture (or 24 hour).

Exit - Return to Windows.

DISPLAY ********

KWH - Click to display captured data (following CAPTURE)

Alternate - Click to toggle display mode to KW, then click KWH

Reconcile to - After placing the kwh from your utility bill in

the bottom kwh box, click to force data to add up to this

new value. Click DISPLAY again to see the result.

Temperatures - If thermistors are used to collect temperature data

on unused kwh channels, the results will be displayed separately

from the kwh data. Alternate toggle selects degrees C.

SETUP ********

CT - Enter CT descriptive data on this panel.

microMETER - Use to enter global data for all the mM channels.

RESET ********

Selective - Click to reset any channel(s) with a lowercase "r" entered

at the leftmost position of the circuit name box.

All - Click to generate billing data and clear the kwh readings.

Print Bills - Click (after a RESET) to print the billing data.

Unreset - Restores ALL kwh accrued since the mM was installed.

This is NOT used in normal monthly billing procedures.

ABOUT ******** Displays "ABOUT" information

HELP ********

Readme - Displays the README.TXT file

Readme2 - Displays the README2.TXT file

24 HOUR DEMAND ********

Process New Data - After a 24 hour capture has been completed, click

this entry to process the data. It takes about 15 minutes and only

needs to be done once. Any previous demand data graphics will be

lost. If desired, save the USAGE.Pxx, DEMxx.Pxx files first.

View - Access any of the processed data. Note that interval demand

data will not be available until processed by the PROCESS DEMAND

entry at the end of this menu.

Instantaneous Select - After viewing any interval data, click to make

View show the instantaneous graphs again.

15 Minute Select - Changes View pointer to 15 minute graphs

30 Minute Select - Changes View pointer to 30 minute graphs

60 Minute Select - Changes View pointer to 60 minute graphs

Process Demand - Click to further process the 24 hour data prior

to viewing any intervals (15, 30, 60). This takes a few minutes

and is only run once for new data.

download

Software Functionality

- 13 -

Software Functionality

This metering software renders an itemized bill by individual

circuit breaker. A call (via modem or direct) is initiated to

the microMETER (tm) from the PC. The microMETER's (tm)

program responds with a stream of data containing circuit

identification, instantaneous demand and integrated power for

each of 16 circuits.

The screen fills with five columns containing the circuit

number, custom description, amperes, kilowatt hours and

dollar cost. The screen is date and time stamped. A setup

option permits the user to update the custom descriptions,

CT calibration factors for amperage and energy costs.

Other options allow reset (and unreset) of kwh column values.

The unreset display shows the monotonic increasing values

coming from the microMETER (tm). Like an odometer, they may

eventually wrap in 85 or so years, but that can be easily

accommodated by the user's descendants. Continuous logging is

also available. Dual monitoring using RMS and true power

setups can uncover power factor problems that can be wasting

energy dollars if left uncorrected.

- 14 -

Identifying COM ports on your PC.

The Windows program Cap2002.EXE can utilize COM 1,2,3 or 4.

The Windows program MICROM.EXE can utilize COM 1,2,3 or 4.

The DOS program MCAP.EXE can only utilize COM 1 or 2 (with modem support).

The DOS program 3CAP.EXE can only utilize COM 1 or 2 (for three-phase).

The DOS program MMICAPPG.EXE (provided by Lockheed Martin) can access

COM 1 thru 4 but does not have modem support.

Each PC is different, sad to say. A DOS PC (without a mouse)

usually has COM 1 or 2 available in the back. The connector

will always be male (pins sticking out) and may have 9 or 25

pins in two rows. Do not try to use a printer port (25 holes

instead of pins).

A PC with an internal modem will tie up one of the COM ports.

A PC with a mouse will (likely) tie up one of the COM ports.

A PC cannot use COM 1 and COM3 together because they share

IRQ4. A PC cannot use COM 2 and COM 4 together because they

share IRQ3. If the PC has a mouse and a modem, and is

properly configured, the mouse is on COM 1 and the modem on

COM 2. If your PC has both, you can use the mouse port by

exiting Windows and running one of the DOS programs for the

duration of the Capture. (Unplug the mouse and connect the

mM until 16 readings have been made.) You may then view the

results with the Windows program or use DIS.EXE (DOS),

available as a download.

Invoke a terminal emulator program such as PROCOMM or Windows

HyperTerminal. Set the parameters to 300 Baud, 8 bits, no

parity and attempt to read the microMETER output directly. It

will appear as a stream of 4 numbers (separated by commas)

every ten seconds. These values must be interpreted by the mM

software to yield correct KWH data.

- 15 -

Combining Time Intervals

Conceptually, the CT.CAP and MICRO2.CAP files hold the latest

"meter readings" and the corresponding time stamps. The

CT.RES and CT.DTE files are copies of this data made at the

time of the last RESET. This is like the "meter readings taken

last month". Both DISplay and RESET use the differences of these

files to produce the new KWH consumption and the time period involved.

If two complete sets of data were created for different time intervals,

a single time interval can be easily created. For example, you have a

complete set of files for April and another set for June.

The April data had a CAPture followed by RESET done on the 1st.

The June data had a CAPture done on the 31st. If you take the CT.RES and

CT.DTE files from April and the CT.CAP and MICRO2.CAP files from

June and put them in the same directory, the resulting DISplay will

show KWH that accrued from April 1 to June 30.

The new CAP2002.EXE program saves every capture in MM.DB1. This file will

allow new programs to reconstruct any billing time period easily and create

graphs and statistics without relying on continous demand capture. It also

generates the legacy .CAP files for full backward compatibility.

- 32 -

mMI prior to 1996

*** ANSI tests:

ANSI C12.1 testing of three microMETER units at Lockheed

Martin has demonstrated accuracy to be +/- 2.3% over all

conditions.

The tests also indicate that the system is suitable for 50 Hz

installations.

*** Larger CT capacity or clamp-ons:

CT's may be purchased from other suppliers that convert say,

1000 amperes to 5. Any CT that produces a 5 ampere metering

current can be read by a CT20 with four passes quite

accurately. Example, you use a 500:5 commercial CT as a

"front-end". Take one of its leads and make 4 passes through

a CT20 and short it to the other lead (see illustration).

When 500 amperes flows through the window of the big CT, 5

amperes will flow in the secondary, appearing as 20 amperes

to the CT20. Enter 500 in the software SETUP since this is

the effective CT size. A small phase shift will be added by

the extra CT but should be negligible for most submetering

applications using true power. Compensation can be applied on

special request. There is no effect on apparent power.

CT20 _ 500:5

| |

H2||H1 put X1 in at H1 H2|_|H1

X1 - ----|| <-------------------< X1 ---|

X2 + ----| X2 ---|

12/30/99

A custom switch, not based on a mM board is available that can

switch a few mM's automatically - cost is about $50 per mM.

*** Scale 2 pre-set:

Software distributions may contain a value of 2516.447

instead of the theoretical 2390.625. This was to provide

better "out-of the box" kvah accuracy prior to

reconciliation. It assumes an overall power factor of .95.

*** Special Hardware Applications - 10/17/95

Time-of-Use can be implemented two ways. Dual mM's recording

night and day with the same CT's or a modified mM with a

variable sensitivity. The latter works but deals strictly

with cost units rather than pure KWH. Power factor analysis

(with correlated data) can be done with dual mM's reading the

same CT's. Set one in true power mode, the other in apparent

power mode.

- 33 -

Network True Power (mMI)

Uses standard CT's (no PCCT's)

For each 24 apartments, 48 channels will be assigned as

follows:

Apt# mM phase A mM phase B mM phase C

1 1 1

2 2 2

3 3 3

4 4 4

5 5 5

6 6 6

7 7 7

8 8 8

9 9 9

10 10 10

11 11 11

12 12 12

13 13 13

14 14 14

15 15 15

16 16 16

17 17 17

18 18 18

19 19 19

20 20 20

21 21 21

22 22 22

23 23 23

24 24 24

The MAP.EXE program and CT.AFF are used to create CT.BIL

for 24 apartments. SUMM.EXE can be used to reconcile for all

apartments.

The above is the "government" way to submeter open-wye. A cheaper

way to do it follows:

Domestic open-wye (120/208) circuits can be treated as 1 phase

for percentage billing purposes if both wires can fit through

the 1/2" CT opening. Demand accuracy in this case is +/- 8% but

it evens out quite well for each tenant's total monthly usage.

- 34 -

Installation for a 3-phase mMI array (deprecated - use mMII)

CAUTION: Commercial (3rd party) CT's produce hazardous

secondary voltages. These leads must be shorted together when

operating. Our CT's are as safe as a flashlight.

Description:

The A-phase J-box is on the left and is connected to B-phase

J-box via 3/4" PVC tee, opening downward. The C-phase unit,

on the right, is directly connected to the B-phase unit in

the center. Three 9-pin computer connections exit on the right.

The shortest runs all the way back to the A-phase unit on the left

(and so on).

The PT connections are to be made to the 6-terminal barrier

strip. The microMETER CT connections are made to the internal

terminal boards. The first has been done as an example. The

CAT 3 enters the tee and splits left and right. The C-phase

pairs (blue and blue white) tunnel over to the far right J-

box. Locate the array centrally to the anticipated CT

placements. Unroll the attached CAT 3 cable and cut at the

desired length to reach the first load.

Mount the three PT's (24-volt control transformers) together

where they can be controlled by a 3-phase circuit breaker.

Identify the 3 primary common wires and connect them

together. If there is a neutral at ground potential, include

it in this connection. Connect the appropriate primary leads

to the A, B and C phases. For a 480-volt delta or wye, the

primary voltages should be 277 volts, since the primaries

will be connected as a wye. The 24-volt secondaries will have

color-coded leads or terminals but may not be marked for

phasing purposes. Connect each secondary in a consistent

manner to the color-coded pairs of a length of CAT 3 cable

long enough to reach the six-terminal barrier strip (on the

mM array). Use the following rule:

A-phase orange and orange-white

B-phase green and green-white

C-phase blue and blue-white

Tie off the brown pair.

At the array, connect the orange-white to the 1st terminal

(marked). Connect the green-white to the second. Connect the

blue-white to the third. Do not connect the others yet. Apply

power and verify that voltages between any two unconnected

secondary wires is approximately 50 volts ac and that voltage

between any unconnected secondary wire and the connected wire

is approximately 29 volts. (This is normal for unloaded

secondaries).

Turn off the breaker and connect the orange, green and blue

wires to the 4th, 5th and 6th terminals, respectively. This

can be done later if you need the breaker on for other

reasons. Tie off the brown pair.

The CT connections at the first load can be made in

accordance with the hookups described in README2. DO NOT

connect any CT type other than the microMETER CT's to the

CAT 3 cable or the microMETER units. Use the same color

coding (above, for PT's) and install them the same way. In

the end, if the phasing is incorrect, all we need do is flip

the PT connections (no big deal). A good rule to follow is:

H1 faces the source of power (usually the breaker). H1 and H2

are marked on each side of most commercial CT's. The 5-ampere

secondaries are marked X1 and X2. The X1 is always the same

phase as H1, so treat it as the "source" for a microMETER CT.

The H1 side of a microMETER CT is the side without the wire.

You put the X1 lead in thru the H1 side. This keeps the

phasing consistent. MicroMETER CT's have two leads of the

same color but different lengths (DO NOT TRIM EVEN!). The

long one is the "X1" or "+" to the mM processor. The idea

behind using microMETER CT's to read commercial CT'

secondaries is to gain the ability to use thin Class 2 wiring

for unlimited runs and to scale the range properly. Scaling

means to "max out" the microMETER CT with enough passes of

the big CT's secondary when it "maxes out". The software is

given the real capacity of the big CT, rather than the size

of the microMETER CT so the readings are correct. Usually 4

passes are made with a 5-amp secondary thru a CT20.

Sometimes, to improve resolution at the normal operating

currents, additional passes are made and/or a different mM CT

is used. The software must always be loaded with this "max

out" value.

- 36 -

Powerstats Kit (mMI only)

The Powerstats Kit is a means of toggling back and forth between

apparent power and true power for the purpose of deriving power

factor data, KVAR, etc. It is a solid-sate relay* that replaces the

selection jumper. It can be controlled a number of ways, by a PC, a

manual switch, or the mM itself. By grounding the white lead, the mM

changes from true power mode to kvah mode. By tying this wire

to the LSB contolling the MUX, even-numbered channels read true power

and odd channels read apparent. By hooking CT's to paired channels

we get an eight-channel analytical meter. This is done by stripping

1.5" from the "+" lead and folding back 1". Bend the folded part back

with an eighth inch radius to form a bifurcated "plug" to enter

adjacent terminals. Pair the odds and evens of the + connections this

way. For the - connections (which are common and connected together),

this bifurcation is not necessary. If using #24 wire, strip 1" and

fold back half for a better grip and wire only the odds (or evens).

Note: Terminal Board C is marked incorrectly. The + side is closest to

the ribbon. DO NOT OVER TIGHTEN THE SCREWS. If you damage a trace on

the Terminal Board, you can pick up the connection again at the

corresponding pin that rises from the center.

* This exotic little part (from Lockheed) has been cleverly replaced with

the following (some time in 2003):

A 2N2907 pnp transistor is installed with the emitter connected to the

rms (ap) selector pin. The collector is connected to the center pin

(a/d input) and the tp pin. The base is connected via a 1 meg resistor

to the MUX lsb. When the lsb is low (for the odd channels), the ap output,

which is always > or = 0, will turn it on. This makes the a/d input follow

low Z signal from the rms ap measurement. When the lsb is high, the

transistor is off (not there) and the a/d input follows the high Z signal

from the multiplier (tp) measurement which we shorted together. This works

well as long as two conditions are met. The rms signal of interest

is above the .6 volt threshold to bias the transistor. And, any unused

CT connections are jumpered to avoid a high rail voltage from the MUX

(which registers a full scale signal in rms (ap) mode and (by saturating

the transistor) in tp mode. It has worked very well in analytical apps

thus far.

- 65 -

Addendums

Addendum 01: Terminal Board B - Loss of Continuity. + and -

re: Equipment sold before Aug 14, 1998

The new strips have wire receptacles that tend to rotate

and tear the foil traces if they are overtightened.

If a trace is damaged, solder a short piece of bare #28 wire

between the DIL pin and the its corresponding screw terminal.

Addendum 02: Terminal Board C, Ribbon Cable Assembly C

re: equipment sold after Aug 14, 1998

An improved Terminal Board and Ribbon Cable Assembly allows

better clearance for making CT connections to the microMETER.

This assembly has a 1.5" Ribbon Cable which attaches to the

rear (trace) side of the Terminal Board. This reverses all CT

+ and - connections as marked on Terminal Board B.

The markings on the trace side are now incorrect. The terminal

strip farthest from the DIL pins is -, The closer one is +.

New units are shipped with with CT (or wire segment simulating a CT)

connection on 1st terminal pair with long and short leads connected

appropriately. Fish paper insulator is eliminated.

General Information

- 80 -

Overview (USDOE)

microMETER was funded by the US Department of Energy to develop a

commercial energy-related product of value and create job opportunities

for former defense-industry personnel. In addition it employs disadvantaged

and handicapped workers where their efforts can contribute to a quality

end-product.

microMETER is a power telemetry system that allows you to read KW and

KWH on multiple circuits using a PC (and modem, if remote). Uses include

submetering shared facilities and automatic meter reading in residential

apartments. Temperature, KVA, KW, KVAR, and power factor data is

available with options. Useful for proving energy management devices.

A basic system comes with a microprocessor unit (4"x4"x2") a potential

transformer (PT), 16 current transformers (CT's) and software for DOS or

Windows. This includes limited installation support and planning (2 hours

per mM unit). The unit price is $990 (US) for 1 standard KW/KWH system.

Each unit meters 16 points and the price-per-point can approach $60 in

larger installations. Dual voltage service points (120/240, 120/208, etc.)

may require an additional CT ($20). Higher voltage points 240, 480 etc.

will require a different PT.

Larger installations can be "networked" so that one phone call can read 256

user "meters". Energy usage graphics are easily produced with the aid of a

dedicated PC. Third party supplier has ACCESS-based municipal billing system.

The device was developed under a USDOE grant and a patent has been applied

for. It was listed by UL 8F84 and was tested according to ANSI C12.1

standards. The overall accuracy is +/-2 % based on test results. In actual use,

the device is easily reconciled to a utility's billing so that users are

billed in measured proportions that add up exactly to the utility's master

statement.

The device can be used in 50 or 60 Hz systems operating at 600 volts or less

with currents of 200 amperes or less. Larger currents can be read with the

addition of 3rd party CT's to the total package. Single phase, split single-

phase (Edison) and open-wye (three wire, 120 degree phase) can be measured as

true power. Three phase unbalanced loads may be measured as kvah or

by utilizing three microMETER's since each has one voltage reference.

- 81 -

Fine Tuning

If there are major differences from the utility meter, see Troubleshooting.

Slight discrepancies can occur in normal use for the following reasons:

* The "CAPture" doesn't coincide with the meter reader's

visit. This is especially true when a utility bill arrives

several days after the meter was read. The software allows

reconciliation to divide the utility bill exactly among the

users each time it arrives.

* Your average line voltage is not correct in SETUP.

* Power factor information is not correct for all circuits.

* A different transformer is used for true power readings.

The original (Basler) transformer produces 29 volts with

exactly 120 volts input. Measure your input and output

voltages and perform the following calculation for correction factor CF:

CF = (Vout / Vin) x ( 29 / 120 )

Multiply Scale2 by CF to correct for this. Also note that

the design transformer inverts the phase and any substitute

must also. If the primary hot side has a dot marking, the

secondary side with the dot goes to the mM black lead (ground)

and the opposite side goes to the mM yellow lead.

The simplest remedy is to alter Scale 2 after enough time has

passed to obtain a good replacement value. Use the RECONCILE

option in the DISplay program to suggest a new value after

several days have passed since the last RESET.

Then, use the SETUP program to permanently change Scale 2.

NOTE: If there has been a loss of data due to the mM being

off, you can use RECONCILE to allocate costs, but do

not change Scale 2. Do a RESET 17 to get things

straight again.

Scales 1 and 2

Scale 1 is a constant (12.75) for your microMETER hardware

version. Scale 2 (2390.625) based on normal 120 volt

service. In some geographic areas the line voltage will

average something different (110-125). This will cause the

microMETER values to differ from the absolute utility value.

After a few days's operation, the Scale 2 value can be fine

tuned to better match your utility bills.

- 82 -

RMS vs. True Power

RMS measures kvah with better than 2% accuracy

and simple installation. For high power-factor loads (typical

household) or similar loads being shared, RMS is recommended.

Known power factor corrections can be applied in software.

Apparent KWH is measured with the industry-standard chip

(used in precision instrumentation) from non-polarized

current signals. The rms measurment responds to the

equivalent heating power of the waveform being measured,

yielding accurate readings for signals from pure sine waves

to complex waveshapes such as distorted sines, squarewaves,

pulses, noise, switching power supplies signals, and more.

Internal jumper block is factory set to select RMS.

True power installation requires more planning, correct phasing,

more wiring and, sometimes, more mM channels and CT's. It

requires 48 channels (3 mM's) to meter 24 apartments served

from 2 of 3 phases from a 120/208 wye service. With 120/240

service, 48 channels can read 48 apartments as true power.

True power measurement requires more processing and depends

on the instantaneous product of properly phased voltage and

current signals. CT's must be properly polarized and the

potential transformer (PT) must be correctly polarized. For

reasons of economy, the 24 volt power transformer for the

microMETER doubles as a rudimentary PT. Only CT's on the same

phase as the power transformer (or reversed single phase "B"

side will be accurate. Different breakers are OK, however.

Phase shifts in all transducers must be corrected in the

calculation to approach the accuracy possible with RMS. Only

partial compensation is provided in the supplied equipment.

Reversed phasing results in zero power indication in the

microMETER. Compare to RMS readings to detect improper

phasing. Net negative power will not register or reduce past

consumption in the registers. This means if you generate

power on your side of the microMETER, it will not "run in

reverse". Ampere readings are derived from the true power

signal and are actually watts / assumed volts. A proper

installation should yield better than 5% accuracy using the

supplied components of the microMETER. For "network" power

(120/208), PCCT's will be needed. Change the jumper block

to select True Power (see README2).

NOTE: Verify operation in RMS (default) mode. When changing

over to True Power, zero ampere readings that should

not be zero are phased incorrectly. It is hoped that,

if any circuits are affected, that all are affected.

The remedy would then simply be to reverse the yelow

and black power connection.

Set VREF to 5 volts ac (RMS). Units after #029 have a

fixed ratio.

>>> 120/208 Wye using (discontinued) PCCT

Identify the leading phase with the following tester:

60 watt bulb 60 watt bulb

A ph ----0-------------|-------------0---- B ph

|

|

|

15 watt fluorescent ballast coil (.75 henry)

|

|

|

neutral

The leading phase will have the dim light and the lagging

phase will have the bright one.

From the original phase corrected CT (PCCT) design spreadsheet:

SENSE CAPACITY BURDEN Steel

4,2 20,40 8 16" A

5,3 60,100 31 57" clip 2" M

4,3 150,200 58 99" clip 2" A

PCCT

CT 60 deg network shift 8/19/95 ICE (delay E) PCCT

load r ser r cap phas volt xC

1500 0 1 60.51242 0.011321 2652.582 12.35294

0.492234 <--this output needs to be doubled

1500 0 1 60.51242 0.020020 2652.582

0.870462 -60 -3

A PCCT is made by doubling the sense winding turns, attaching

the + lead to a 1 uf capacitor, then driving a 1500 ohm resistor

load with the bottom end attached to the - lead.

This was series-added to the regular CT and presented to the mM channel.

3-phase tutorial

Power factor and 3-phase load testing can be done by driving large

audio amplifiers from sound card.

network feed

open delta

120 volt open delta

120 volt wye

120 volt wye

3ph text

3ph spreadsheet

- 83 -

Troubleshooting

12/24/05 - Cap2002v15 - Due to recent reported difficulties with com port processing, Cap2002v15 is

supposed to help. Something has changed in Windows or its service packs that is confounding the

original code in Cap2002, which already had a Microsoft recommended fix applied to it. The capture

and display programs are both "smart" enough to tell a mMII processor from a mMI. If the string is

longer than 18 characters, it must be a mMII. The problem begins when Cap2002 thinks a string from a

mMI is longer than 18. Fortunately, I was smart enough to separate the Capture from The Display

functions as I originally did in DOS. Comport connectivity has never been easy with Windows and

keeps getting worse. The problems were noticed first on Compaq, and later, a Dell (with other

driver problems as well). Trying to fix the existing code is like nailing new wood to rotten wood. A simple

modification as Cap2002v15 "csamp" treats any input as mMI and ignores extra numbers in the stream.

*** Dis2002 failing to load mm.db1 - 12/28/05:

"Problem with file mm.db1 or directory structure" - Last debug milemarker: 2 5

This is caused by an anomaly in the mm.db1 file. Make sure all lines are the same length. Failure of Cap2002

to read a Type I processor (mMI) and store the data in lines of length 350. This is apparently due to MS changes

outside of Cap2002 (see below). Once this file contains uniform Type I entries, Dis2002 will perform

correctly on any computer. If Cap2002 is failing, the remedies include:

1) Use Cap2002v15 which has been altered to process only mMI.

2) Try another computer, older might be better.

3) Use Emu2002 to add data to mm.db1 that has been obtained from Hyperterminal

Identifying COM Ports on your PC.

4) Use Cap2006 to add data to mm.db1 that has been obtained from Hyperterminal

Identifying COM Ports on your PC. Requires MS .net

1/5/06 - Windows does not recognize the file suffixes .dat and .db1 as text files.

Right-click open and "choose program from a list" (notepad)

Check the box below to always open with notepad.

Example of anomaly: The 1st 2 entries are normal mMI lines. The 3rd entry is defective.

mm0120051012114916,01,035,10924,00175,02,012,61364,00053,03,007,41013,00105,04,005,12325,00105,05,006,37139,0004

2,06,016,35389,00135,07,003,48547,00045,08,009,03565,00131,09,012,36775,00307,10,255,29701,01043,11,255,33106,01

043,12,255,30224,01043,13,255,42609,01043,14,255,34848,01043,15,255,32878,01043,16,255,29647,01043

mm0120051012115446,01,030,10988,00175,02,010,61384,00053,03,000,41013,00105,04,005,12334,00105,05,006,37151,0004

2,06,016,35421,00135,07,009,48565,00045,08,009,03583,00131,09,012,36799,00307,10,255,30211,01043,11,255,33616,01

043,12,255,30734,01043,13,255,43119,01043,14,255,35358,01043,15,255,33388,01043,16,255,30157,01043

mm0120051104163645,01,023,51689,00177,000,00001,00023,51689,02,009,26310,00057,000,00002,00009,26310,03,003,6164

4,00107,000,00003,00003,61644,04,006,21689,00106,000,00004,00006,21689,05,019,27440,00044,000,00005,00019,27440,

06,016,20304,00139,000,00006,00016,20304,07,9704,00133,00000,008,00007,09704,1111102,009,26310,00057,000,00002,0

0009,26310,03,003,61644,00107,000,00003,00003,61644,04,006,21689,00106,000,00004,00006,21689,11,255,14442,01092,

000,00011,00255,14442,12,255,11560,01092,000,00012,00255,11560,13,255,23945,01092,000,00013,00255,23945,14,255,1

6184,01092,000,00014,00255,16184,15,255,14214,01092,000,00015,00255,14214,16,255,10983,01092,000,00016,00255,10983,2

*** Discrepancy with another meter:

Be sure you read the other meter correctly and apply any multipliers

used by your utility.

*** Scale 2 (SCAL2) pre-set:

11/25/04 - All s/w is now set to theoretical value. mMII does not need this correction.

Earlier software distributions for mMI may contain a value of 2516.447

instead of the theoretical 2390.625. This was to provide

better "out-of the box" kvah accuracy prior to

reconciliation. It assumes an overall power factor of .95.

If you change the jumper from rms to tp (true power), the

theoretical value should be used. Change this in MICRO.DAT.

*** Crazy data:

Try RMS (default) mode. View the incoming data directly with a modem

communications program. If it appears "Geek" then check PC

serial parameters. Baud rate must be 300. See Protocol.

Reversed connections in the data line can cause this.

If protocol appears clean but values are strange, work with a single,

well understood circuit.

Be sure CT's are connected properly to their own pairs of

terminals and that there are no faults in extended wiring.

Strong radio frequency interference may be a reason. This happened

once near a radio tower but we fixed it. Call us for help.

High, erratic readings can indicate a defective CT. An open burden

winding due to tensile stress or a poor solder connection can cause

this. This is rare but we will replace any such CT's.

Constant mid-scale readings on all CT's can result if the RMS/True Power

jumper block is missing. Neither RMS or true

power is selected and the A/D converter input "floats". (Type 1)

*** Empty file message or failure of program to run:  old programs

old programs

Several files must be present for the PC software to

work. If one or more is missing or damaged, this message will

appear and the program will crash. The most common cause is

an unsuccessful or incomplete capture from the mM. The files

affected in this case are CT.CAP and MICRO2.CAP. Recopy them

from the diskette, or capture from COM 5 (MICROM.EXE) to fake the readings.

Determine the cause of the real capture failure. See "No data"

and "Crazy data" below. The final remedy is a successful capture.

Be sure to allow 3 minutes for it to complete and listen for the

beep.

5/6/05 - A year-2000 installation using a Gateway 2000 running Windows 95 was unable to use

MICROM.EXE to read a second, newly-installed processor with the "file/directory" dropdown choice.

Other installations with more than one processor have not experienced this problem. It

was confirmed this same day that MICROM.EXE could perform properly on another pc. The error

messages were strange ones about "com4" and empty files (all were present after restoring from

backup). I suspect a memory, or other pc-related, problem. MCAP (DOS) was used to get the

readings and a new pc will be obtained that can run the new s/w.

Table 30a (from README2) - (The OLD WAY)

mMI mMII function

1 green white w blue rs232 return

2 red blue (w white) rs232 data from mM

3 black white w orange PT return

4 yellow orange (w white) * PT 29 vac A phase

5 white w brown * PT 29 vac B phase (with internal Phase Selector only)

6 brown (w white) * PT 29 vac C phase (with internal Phase Selector only)

7 white w green R2 select C phase instead of B phase

8 green (w white) R1 select other phase than A phase

Note: The Phase Selector was originally planned as an internal component. It is now attached

between the Type 2 processor and the PT's according to the following table. Note that the blue pair

bypasses all of this and only connects the mMII to the computer com port. The terminal board is

part of the Phase Selector Assembly.

The use of this component in combination with a Type 2 (mMII) processor will measure each of the

three phases of five 3-phase loads. The 16th channel is a remaining A-phase input and is not

generally used. This allows a compact, single-processor solution for a small bank (5 or less) of

3-phase loads.

04/22/2008 - Software installation w/o CD:

Or by Downloading:

Step 1 - Create a new directory called micromtr on your pc desktop.

Step 2 - Download files (right click, save link target as) and place them in micromtr

Cap2002.EXE

Dis2002.EXE

b.gif

mscomm32.ocx

msvbvm60.dll

Step 2.1 - Create subdirectories mm01, mm02, test..., under micromtr.

Step 2.15 - Run Cap2002, select above subfolder, change "obs" from 1 to 0, click "Init" button

OR

Step 2.2 - Download non-customized

mm01.zip (unzip this)

and place in micromtr\mm01\.

Step 2.3 - Be sure micromtr has subfolder(s) mm01, etc. and that subfolders mm01, etc.

have no subfolders inside.

error reporting (old)

The best way is to zip the entire contents of the subfolder (mm01, etc.) and send by email

as an attachment. Download and save PKZIP.EXE in the

subfolder. Start a command prompt (Start, all programs, accessories) and navigate

to the subdirectory (cd .. as needed, then cd micromtr/mm01). Now type:

pkzip errors01 *.*

This will produce a file called errors01.zip with everything needed. Alternatively, to